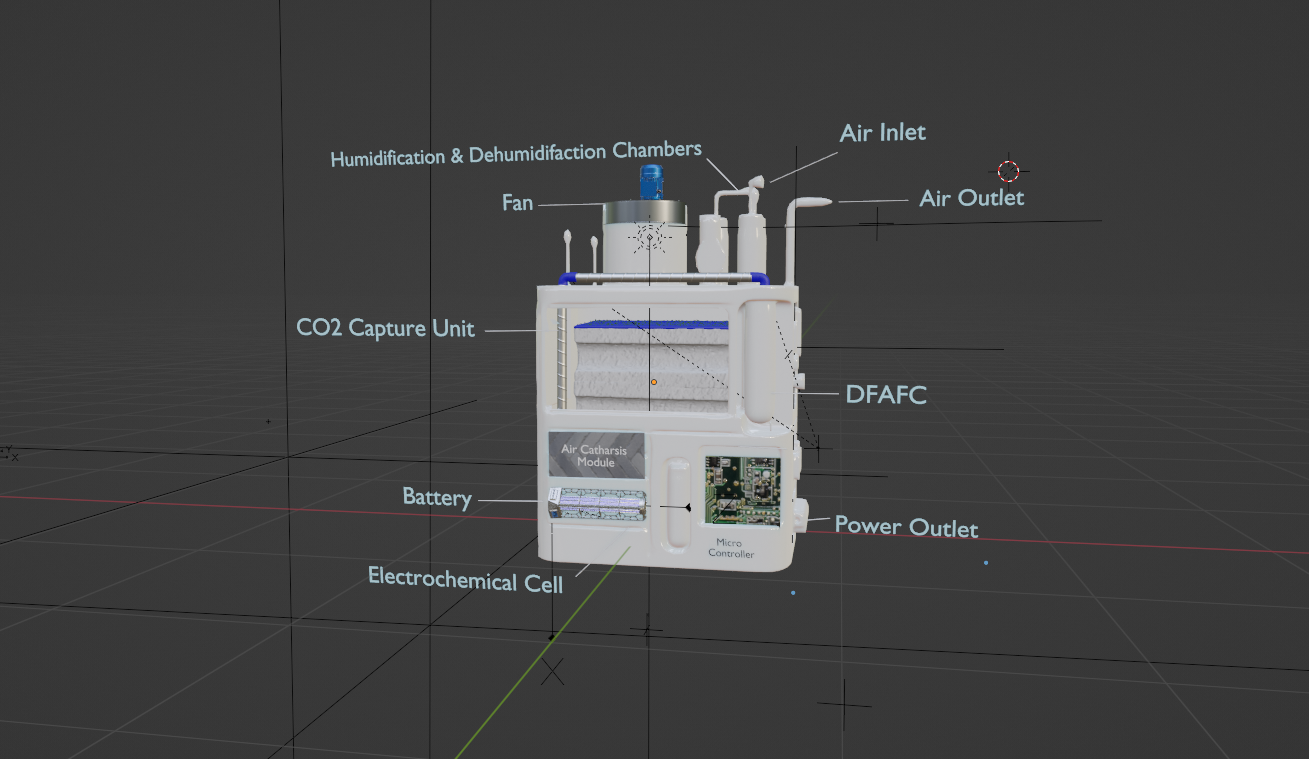

Symbiotic Air Catharsis Module

Integrated indoor air purification, CO₂ capture & energy recovery

Overview

The Symbiotic Air Catharsis Module is an integrated environmental system designed to purify indoor air while simultaneously capturing carbon dioxide and converting it into usable electrical energy. The system combines chemical sorption, electrochemical conversion, and fuel cell technology into a compact, energy-efficient module.

The design prioritizes low energy consumption, indigenous materials, and modular scalability for household and industrial applications.

System Architecture

Complete system architecture showing all integrated components

CO₂ Capture Module

$$\text{CaO} + \text{H}_2\text{O} \rightarrow \text{Ca(OH)}_2$$

$$\text{Ca(OH)}_2 + \text{CO}_2 \rightarrow \text{CaCO}_3$$

This humidity-assisted pathway improves sorption efficiency while operating at room temperature.

Regeneration - Humidity Swing

$$\text{CaCO}_3 \rightarrow \text{CaO} + \text{CO}_2$$

Dry air shifts the chemical equilibrium, regenerating CaO without requiring high-temperature calcination—dramatically reducing energy consumption.

Indigenous Innovations

• Layered melamine foam with graded pore sizes for optimized airflow • Sensor-driven airflow control based on temperature and humidity • Gravity-assisted airflow routing

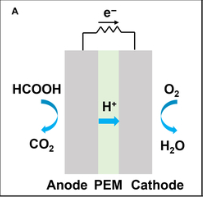

Electrochemical Conversion Module

Electrochemical Cell Design for CO₂ Conversion to Formic Acid

$$\text{CO}_2 + 2\text{H}^+ + 2e^- \rightarrow \text{HCOOH}$$

ANODE REACTION:

$$2\text{H}_2\text{O} \rightarrow \text{O}_2 + 4\text{H}^+ + 4e^-$$

Cell Design Innovations

• Membrane-less microfluidic electrochemical cell

• Tin-based electrodes for cost efficiency

• Potassium bicarbonate electrolyte to enhance CO₂ solubility

• Direct coupling to downstream fuel cell via microchannels

This eliminates the need for expensive membranes and intermediate storage.

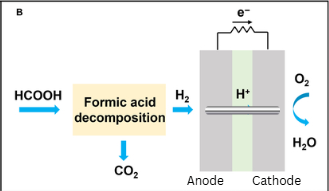

Power Generation Module

Power Generation with Proton Exchange Membrane (PEM) Technology

Advanced Power Generation and Energy Distribution

The Power Generation Module converts the energy produced by the electrochemical cell into usable electrical energy. This innovative system captures the voltage differential created during the conversion process and transforms it into power that can support the overall system operation or feed back into the grid. Key Features: • High-efficiency energy conversion • Real-time power monitoring • Scalable architecture for multiple cell configurations • Integration with grid-tie systems

Fuel Cell Advantages

• Direct coupling minimizes energy losses

• Generates electricity to partially or fully power the air purifier

• Excess electrons can power external circuits

System Flow Summary

$$\text{CO}_2 \rightarrow \text{HCOOH} \rightarrow \text{Fuel Cell}$$

ELECTRICITY FLOW:

$$\text{Chemical Energy} \rightarrow \text{Electrical Energy}$$

Performance Metrics

• VOC removal: up to 92%

• NOx removal: up to 85%

• Energy consumption: 20–30 W/hour

• Carbon footprint reduction: ~30% compared to conventional purifiers

Potential NO₂ Catharsis

$$\text{NO}_2 + \text{H}_2\text{O} \rightarrow \text{HNO}_3$$

$$\text{CaO} + 2\text{HNO}_3 \rightarrow \text{Ca(NO}_3)_2 + \text{H}_2\text{O}$$

This offers a pathway for additional NOx mitigation.

Challenges & Solutions

CHALLENGES

1. Long-term CaO stability

2. CO₂ release during regeneration

3. Scaling electrochemical cells

SOLUTIONS

• Doping CaO with Al₂O₃ / ZrO₂ to prevent sintering

• Partial CO₂ recirculation and algae bioreactor integration (future scale)

• Modular microfluidic electrochemical design

Implementation & Impact

IMPLEMENTATION

• Plug-and-play module for existing air purifiers

• Standalone CO₂ catharsis unit

• Compact, replaceable cartridge design

IMPACT

• Improved indoor air quality

• Decentralized CO₂ mitigation

ALIGNED SDGs:

• SDG 3: Good Health and Well-being

• SDG 7: Affordable and Clean Energy

• SDG 13: Climate Action

Financial Viability

PROJECTED MARKET PRICE

• Household HVAC: $200/unit

• Premium/industrial: $500/unit

• Licensing: $10/unit royalty

PRODUCTION COSTS

• Prototype: $350–400

• Mass production: $150/unit

• Optimized materials: < $90/unit

PROJECTED PROFIT MARGIN: 40–50%

Future Vision

• Scale for HVAC and industrial systems

• Develop nanostructured CaO sorbents

• Advance electrocatalysts for higher efficiency

• Enable decentralized carbon capture worldwide

Clean air. Captured carbon. Recovered energy.